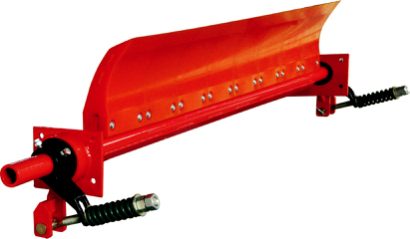

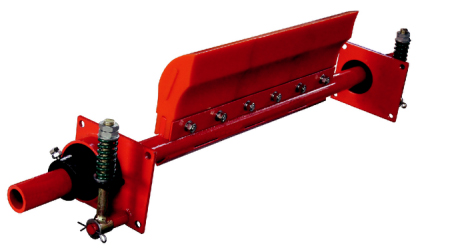

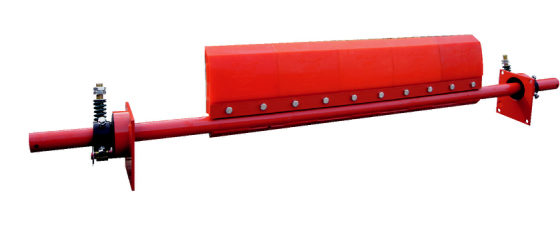

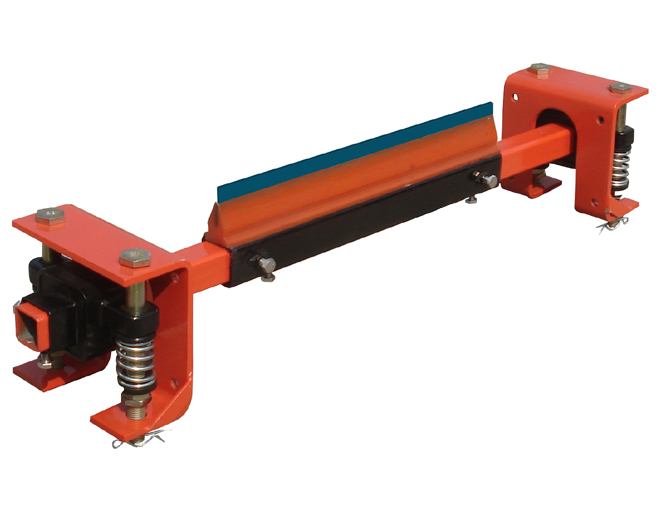

G Force Air cannon

The G Force Air Cannon is a pneumatic, bulk material-moving system that quickly releases compressed air into a storage vessel (bunkers, hoppers, cement pre-heater kiln, pipes, chutes, etc.) to restore flow to material that is clinging, bridging, rat-holing, or arching.

The G force Air Cannon is designed for uses on storage vessels with internal temperatures up to 800℃ and up to 1400℃.

Such product is widely used in industries such as cement plants, metallurgy, chemical industry, coal, power, mine, coal carbonization, steel mills, etc. It’s characteristics are low energy consumption, small investment, easy maintenance, etc, which makes it a kind of ideal equipment for blockage or caking problems used for the above industries.

G Force air cannon, recommended working temperature is -40℃~65℃ and working pressure is 0.4~0.8MPa, is a kind of high-efficiency, environment-friendly and energy-saving product for eliminating blockage and assisting the materials flow.